Description

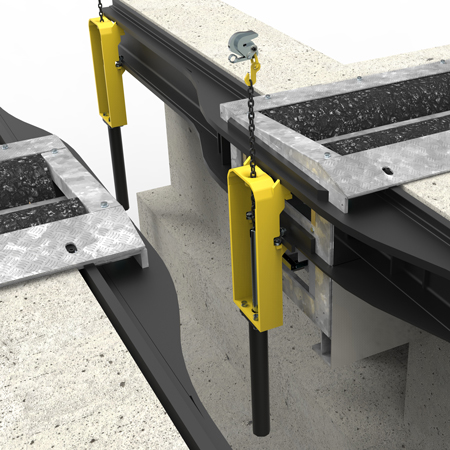

The BM12200 roller brake tester is built to withstand a very high throughput and handle continuous test of full laden axles.

This brake tester features a large range of options that allows for a customized configuration.

obust and long lasting:

All steel is of highest quality and hot galvanized.

Consists of an integral motorized gear box, two main rollers and a spring loaded sensor roller, all placed in a galvanized steel frame.

The wear surfaces of the rollers are based on mesh steel to ensure a long life time and accurate measurements.

All gaps are minimized to protect staff.

Cover plate design around the roller area all have angles to minimize potential tyre damage.

Can be supplied in a minimum configuration and still allows for later upgrade to all options.

Easy to use with BM software:

Integrated guide.

Advanced graphics printout.

Diagnostic printout with or without connection to PC/Notebook.

Calculation of test results according to the requirements of many national authorities.

BM FlexCheck software:

Advanced data collection, storing and presentation of test results.

Data capture from a complete inspection lane.

PDA/smartphone/tablet solution that allows the operator to control and monitor the test results directly on a handheld unit.

Up to 3 displays can be connected.

Optional cable or radio air/hydraulic pressure system.

Optional automatic axle weighing.

Test of 4×4, 6×4 and 8×6 driven vehicles.

Optional cable or radio pedal force meter.

Heating package for outdoor installation.

Optional axle load simulation.

Optional chassis load simulation.

The BM12200 roller brake tester is approved by several international authorities i.e. RWTÜV Germany and complies with the ISO standard.